Inevitably, pipes and drains become cracked or damaged over time, which can lead to environmental, structural and health problems for a premises manager.

The good news is that instead of the age-old solution of locating, digging out and replacing broken sections, there are more efficient and effective ways to repair a pipe or drain, and that’s to reline it.

Options for pipe and drain repair

If a pipe or drain has collapsed, suffered extensive damage and wear and tear along its length, or it’s constructed from a material that’s no longer considered safe, such as lead, then the best option is probably to replace it.

However, this involves excavation along its length, removal and replacing with a new product. You may need to shut off a water supply or bypass the damaged section.

But a lot of this cost, disruption to customers or clients and inconvenience to your operation can be avoided if you only need to stops leaks or contamination. In this case relining offers the best solution.

Lining can offer a long-term solution to cracks, tree root invasion or leaky joints along the whole length of a pipe or drain. There are two main methods used to line a pipe: cured-in-place pipe (CIPP) and slip-lining.

Both processes can be used for gravity sewers, storm drains, culverts, and pressure pipelines with diameters ranging from a few cm to several metres. They also offer advantages and disadvantages while removing the need for major excavation.

CIPP repair

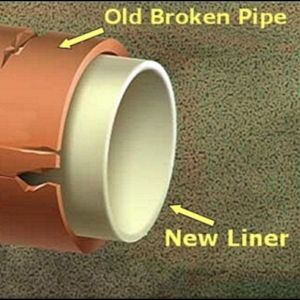

This involves the insertion of a flexible, resin-impregnated tube (usually polyester or fibreglass) into the damaged pipe and inflating it with an airbag or water to push it against the existing wall. The resin is then cured with hot water or steam so that the new liner hardens and sticks to the original pipe wall, creating a seamless new channel.

Slip-lining

A new, smaller diameter pipe is literally slipped into the existing, damaged ‘host’ pipe or drain. This method is typically used where there’s major damage to the pipeline and works best on relatively straight lengths of pipe.

Benefits of CIPP

Relining offers a quicker, lower cost and less disruptive option to digging up and replacing piping, especially for managers of busy public facilities or commercial operations. We find that CIPP, in particular has a number of other benefits:

- Pipe lining reinforces and protects an existing structure from future contamination, cracks and root invasion.

- For pipes, drinking water quality can be better protected from contamination by fungus or mould, metal or other materials.

- Modern CIPP is a resilient solution that lasts for decades.

- It can be used for pipes and drains of any diameter.

- CIPP is more flexible, so you can navigate bends in pipes more easily.

- As it moulds itself to the existing pipe wall, there is minimal reduction in flow capacity.

And end to end repair solution with Drain and Sewer Services

At Drain and Sewer Services we carry out the full repair process, from carrying out a CCTV survey in order to locate a problem, to relining, and finally to inspecting the repaired pipe to ensure the problem is solved.

We also offer a full range other services to keep your premises safe and operating smoothly, either through emergency call-outs or a regular inspection and maintenance programme:

- Drain, sewer and culvert unblocking and repairs

- Floodwater removal

- Guttering maintenance

- Septic tank emptying, repairs and maintenance

- Pumping station maintenance

- Road and drive works

If you need to talk to Drains and Sewer Services about repairing a drain, sewer or pipeline, or any other of our other services, call us today on 01252 312738 or email info@drainandsewer.co.uk for a consultation.